Conference Review

A review of the International EV Batteries 2021 Conference from a wider cooling system perspective

Read our review of the EV batteries technical conference from a wider cooling systems perspective. 15th November 2021 by Andrew McMahon

Snapshot

Event

International EV Batteries 2021: Cost-Effective Engineering for Hybrid and Electric Vehicels.

Location

Kia Oval, London

Audience

Attend the International EV Batteries 2021 conference to hear the latest developments in battery design, testing, thermal management, charging and integration right across the lifecycle of the battery for a more resilient and cost-effective battery.

EV Batteries Conference Review:

The IMechE’s international battery conference was held at the Kia Oval, London on November 9th & 10th 2021. We were delighted to be a sponsor of the event arranged by the IMechE. It was great to see some familiar faces, existing customers and many new faces too, whilst enjoying the fantastic view of the Oval throughout! Read on for our summary of the topics covered, from dielectric to cold plate cooling solutions.

View from the EV Batteries Conference

Dielectric fluids for Immersive cooling:

The last 12 months have seen the rapid pace of development continue around cells, packs and the all-important topic of thermal management. We have seen a number of companies emerge in the world of immersive cooling, so were intrigued to see where the market as a whole is, in terms of immersive cooling adoption and use cases.

For those who are new to immersive cooling, this is the use of a non-conductive dielectric fluid to immerse the cells, either fully or partially and the busbars, in a non-conductive coolant. This coolant has a relatively low viscosity compared to a traditional oil, so we see many applications successfully using a “traditional” water pump product, rather than a specific oil pump. Note that it is important to be mindful of the properties of the fluid you are using when trying new fluids to avoid issues with the materials in the pump seals.

Typically water pumps are centrifugal and are limited by pressure whilst delivering relatively large flow rates, whereas the electronic oil pump is a gear pump (positive displacement) and therefore delivers far higher pressure, but is limited by flow rate.

The trade-off of flow vs pressure is not a new one, but the use of a dielectric fluid does create an interesting pump choice question, one where the answer is typically provided by the internal design of the cooling pack and its associated pressure / restriction to the flow. Whereas traditional pump selection is determined by the fluid’s properties, operating temperatures and then “limited” by the pumps performance.

There was an excellent presentation from Dr Richard Pearson, Senior Advisor, EV and Mobility at BP that comprehensively covered use cases and strategies for immersive dielectric cooling.

What impact does a Dielectric have on the Heat Exchangers?

Modern dielectric fluids are very compatible with traditional cooling circuits, typically the heat exchanger is a radiator when the pressure is low (water pump applications) and an oil cooler when the pressure is high (oil pump applications).

Dielectric considerations:

Cost, weight and complexity vs the benefits…

The general consensus from the industry is that immersive cooling is the way to go for high C charge and discharge, whether this be motorsport or rapid charging. Fears over high weight were somewhat alleviated during the presentations from Ricardo Plc in collaboration with M&I Materials and WMG (Warwick Manufacturing Group). Their presentation also demonstrated a cost comparison against cold plate cooling which prompts some interesting discussion. However, serious R&D is required in order to optimise a pack to this level, therefore immersive cooling probably won’t be your first battery pack, but certainly one to aspire to if your application demands it. Further work is ongoing to evaluate the increased life expectancy and additional range benefits for a battery pack with immersive cooling.

Cold plate cooling by comparison:

By comparison, cold plate battery thermal management solutions are not dead in the water (glycol), not by a long shot. Not only is this one of the most popular current cooling techniques, it is also set to stay for some time. Many OEMs and battery pack manufacturers can maintain acceptable cell temperatures throughout the pack with a water glycol cooling loop and a cold plate with 3 to 5 C charge / discharge rates.

For now, we’ll leave the topic of cold plate cooling, as that is somewhat of a more mature technique, but we always welcome a discussion about specific applications if customer questions arise.

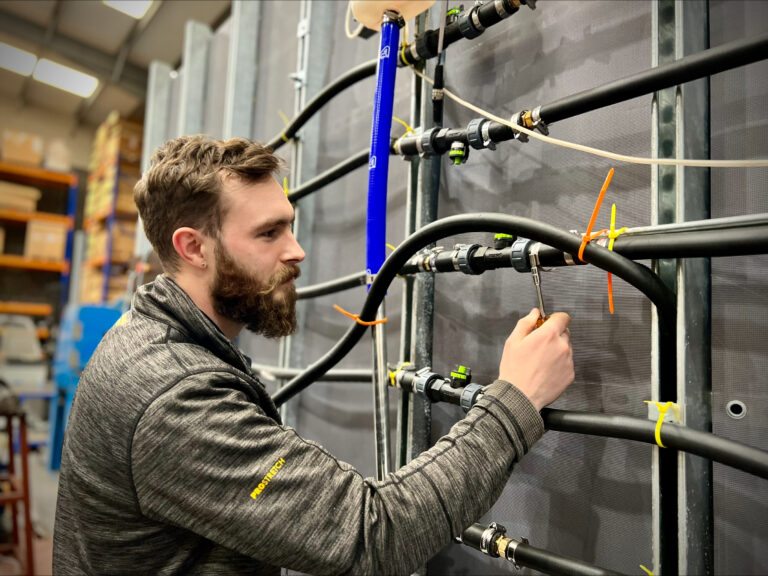

Dielectric and cold plate cooling products for battery and EV thermal management

What is the outlook:

The market is still on a phenomenal growth trajectory, unlike 1 – 2 years ago there is clearly now the investment in the infrastructure required to facilitate this growth with a localised manufacturing base to support this. Excellent examples were presented by Joe Bakaj, Vice Chairman, Britishvolt.

For the consumer, a “little and often” charging strategy at a high C rate with a mature charge network is plausible, but is certainly not affordable for the mass-market low cost EV driver; we suspect the mass-market will be made up of many more slower charging solutions and longer wait times at “the pump”.

Technical round tables:

The thermally minded among us met at round table number 4 chaired by the world famous Cedric Rouaud, Global Technical Expert – Thermal Systems from Ricardo to discuss the topic “Have we reached the optimum performance and cost of battery thermal management solution?”. It was a hot topic and warmly debated by the table, thankfully complimentary beer was provided that evening by our hosts the IMechE to round off a interesting discussion. It was great to see such levels of collaboration alive and well, driving the industry forward thanks to events like this, and the considerable continued support from Government investment.

Over and out:

And finally, yes, the topic of fuel cells has been largely ignored here but that is intentional, as this is coverage of the batteries conference. Rest assured however, fuel cells have a huge part to play in the future of, zero emissions at the point of use powertrains and their rather large heat rejection too… lets have that conversation together soon ????

From all the Technical Services Team, thank you for such a great few days and we look forward to attending again next year!

Attendees from Technical Services:

Sam Harrison – Account Manager

Andrew McMahon – Sales & Engineering Director

Glossary of terms:

- EV (Electric Vehicle)

- BEV (Battery Electric Vehicel)

- HEV (Hybrid Electric Vehicle “Self Charging” or “Mild Hybrid” or “48V”)

- PHEV (Plug In Hybrid Electric Vehicle)

- C (Battery C Rating)

Future events you can meet us at:

- The Battery Show & EV Tech Digital Days – November 17th to 18th 2021 – The Battery Show

- The Battery Show Europe – November 30th to December 02nd 2021 – The Battery Show Europe Conference & Expo | Nov 30 – Dec 2, in Stuttgart, Germany

- Powertrain Systems for Net-Zero Transport – December 07th to 08th 2021 – Powertrain Systems for Net-Zero Transport | London | CON7242 (imeche.org)

- Vehicle Thermal Management Systems Conference (VTMS 15) – June 07th to 08th 2022 – Vehicle Thermal Management Systems Conference and Exhibition – VTMS 15 | Midlands (imeche.org)

Who are Technical Services?

Technical Services is a leading development partner and supplier of vehicle thermal management solutions which also includes the design and manufacture of components and systems for electric (EV) and hybrid (HEV) vehicles. Founded by Gerry McMahon in 1986 from a small workshop, Technical Services has grown to become an internationally recognised thermal management and engine airflow specialist with an enviable reputation for quality, customer service and technical expertise. Technical Services also offers consultancy services, product R&D as well as a range of electrified thermal and oil management components and systems.