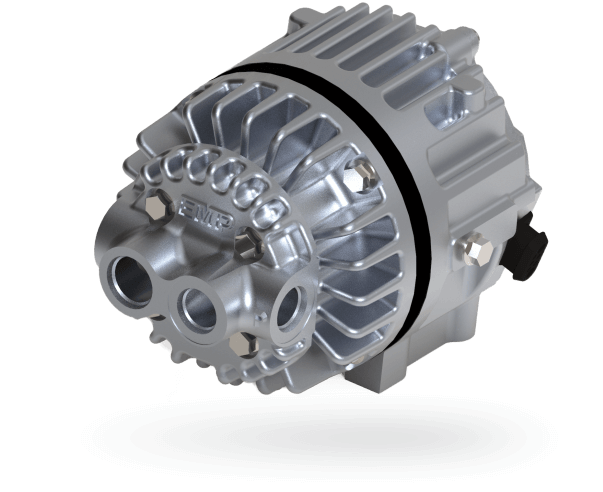

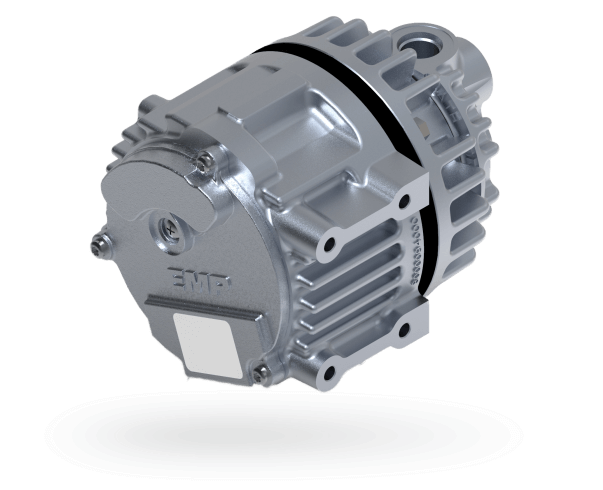

EMP OP80 Electric Oil Pump

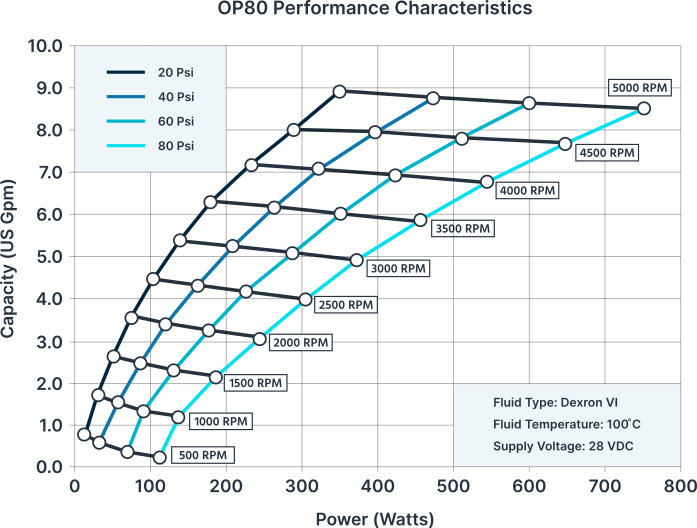

With a flow capacity up to 8 gal/min and discharge pressures up to 80 psi the EMP OP80 Brushless Electric Oil Pump can handle a variety of fluid transfer applications including those for use with motor oil, hydraulic fluid, transmission fluids and gear lubes.

Rated Voltage

14-28 VDC

Size

7.0″ x 5.5″ x 5.5″

Weight

9.5 lbs (4.3 kg)

Flow Capacity

Up to 8.0 gal/min

Optimising systems

and applications as standard

The EMP OP80 Electric Oil Pump is a high performing and reliable cooling component with a large operating range and efficiencies making it suitable for a wide range of vehicles and applications.

High Power Density

The EMP OP80 offers best in class performance with flow capacity up to 4 gpm and discharge pressure up to 100 psi. Efficient mechanical design along with proprietary software allows sub-zero cold start capability.

Self Priming

EMP pumps are all 100% flow tested and incorporate internal geometry features to ensure pump will remain wet for improved priming capability.

Multiple Port Configurations

Pump head has two sets of suction and discharge ports for ease of installation and plumbing.

Communication Protocols

The EMP OP80 can be controlled through the following communication protocols: On-Off, J1939 CAN, PWM , EMP-Link. EMP-Link and J1939 CAN versions allow two-way communication to support diagnostics. J1939 CAN communications support J1939 messages defined for Secondary OBD Devices. PWM version provides tach-out feedback (RPM). Note: Interim solution requires use of TMC system controller.

Brushless DC Motor and Drive Controller Technology

Available with 12 VDC and 24 VDC electric motors, brushless, permanent magnet motors are combined with EMP designed motor control electronics to provide a high efficiency, long life pump. Brushless motors have no contacting parts to wear and reduce life. Features include locked rotor protection, over temperature protection, over current protection, over voltage protection and reverse battery protection.

Positive Placement Design

EMP pumps feature positive displacement gerotor type pumping elements allowing for a simpler, quieter, more compact pump design while improving performance and minimizing power loss.

Sealed and Fully Submersible

EMP pumps are sealed and fully submersible for long life operation when exposed to the outside environment and its elements. The pumps are designed and have been validated to withstand submersion and direct spray pressure wash.

LEARN MORE

Enquire about the EMP OP80 Electric Oil Pump

If you would like to learn more about the capabilities of the EMP OP80 Electric Oil Pump, then please fill in the contact form below and one of the team will get back to you to answer any questions you may have.

"*" indicates required fields