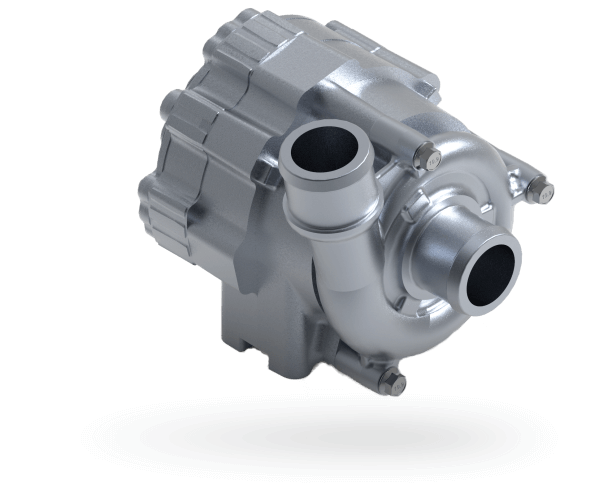

EMP WP150 Electric Water Pump

This hard-working, high-performing and and severe duty electric water pump is ideal as part of a cooling system for use in extreme environments especially within off-road, power generation and large vehicle applications including fuel cell, diesel, electric and other alternative fuel applications.

Rated Voltage

9-18 or 18-32 VDC

Controller

CAN

Weight

15.5 lbs (7 kg)

Target Life

20,000 hours

Optimising systems

and applications as standard

The EMP WP150 Electric Water Pump is a high performing and robust cooling component with a large operating range and efficiencies making it suitable for a wide range of vehicles and applications.

Rugged Design

The WP150 features die cast aluminium castings for strength, durability and improved heat transfer from the motor and electronics. This allows for continuous, high output coolant flow and pressure in extreme temperature conditions, as well as salt, spray, pressure wash, chemicals, or UV.

Lab Tested for Severe Conditions

EMP Pumps are validated to withstand all field conditions including thermal cycles, salt spray, pressure wash, thermal shock, vibration and shock, electrical transients, ESD, reverse battery and more. Durability testing has surpassed 20,000 hours of continuous operation.

Temperature Inputs

EMP electric water pumps have the ability to read external temperature sensors and control speed based on this input. They are also able to broadcast temperatures to the vehicle via SAE J1939 CAN.

Service Tool and Configurations

EMP pumps can be controlled manually using EMPower Connect™ Service Tool enabling software in the pumps to changed or upgraded in the field. Historical data can be downloaded and includes hours of operation, temperature data, voltage data and calibration information amongst others.

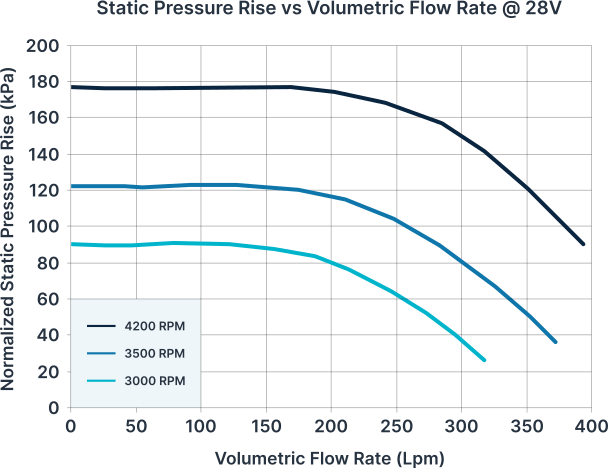

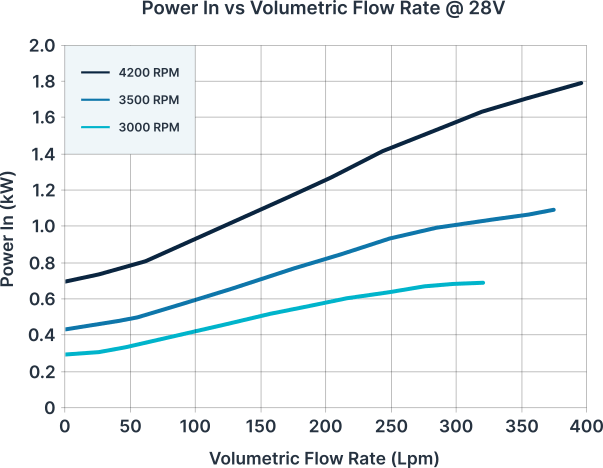

High Efficiencies, Compact and Quiet

The motor, electronics, and fluid design have been optimized for high efficiency. The end result is the highest possible flow and pressure for a given amount of input power. The design is also packaged to have as small a footprint as possible for the given pump performance and minimize sound output.

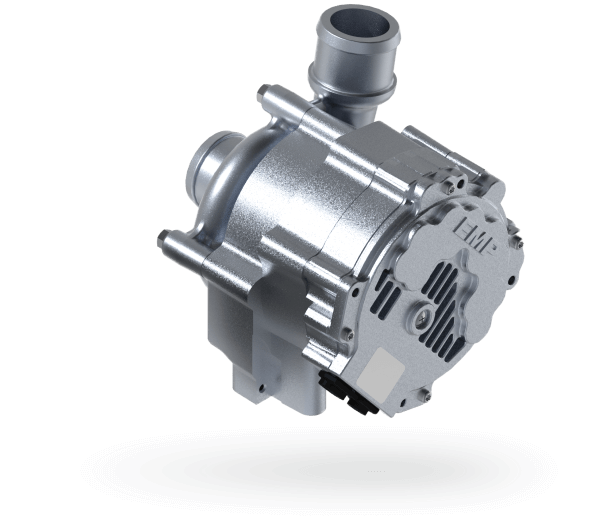

12, 24 or 48 VDC Brushless Motor

Brushless, permanent magnet motors are combined with EMP designed motor control electronics to provide a high efficiency, long life pump. Brushless motors have no contacting parts to wear and feature locked rotor protection, over temperature protection, and over current protection.

Watch our Video on Electric Coolant Pumps

LEARN MORE

Ask about the EMP WP150 Electric Water Pump

If you would like to learn more about the capabilities of the EMP WP150 Electric Water Pump, then please fill in the contact form below and one of the team will get back to you to answer any questions you may have.

"*" indicates required fields